|

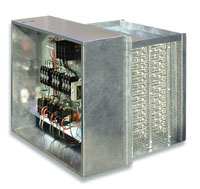

Open Coil Duct Heaters

| The open coil elements are the most popular in the industry,

suitable for most standard HVAC ducted systems. The biggest advantage of these elements is the excellent heat dissipation

capacity with heating capacities ranging from 0.5 to 1000 kW. | |

|

| Features of the Open coil elements |

| • Minimal pressure drop |

| • Fast response time |

| • Up to 40 kW per sq.ft. |

| • Quick delivery |

|

| The grade C open coil elements type is made up of nickel, chrome

and iron. Neptronic® offers, for applications in humid environments, NiCr 80 (grade A) elements which do not contain any iron.

| |

|

|

|

|

Tubular Duct Heaters

| The Standard and Finned tubular type offers an excellent mechanical

resistance, suited for demanding environments. These elements are less sensitive to humid and dusty environments but offer

a slower response time. | |

|

| Features of the standard and finned tubular elements |

|

| • Up to 13 kW per sq.ft. (Standard) and Up to 15 Kw per

sq.ft. (Finned). |

| • Heating elements not in direct contact with air. |

| • Element of U or W shape. |

|

| Tubular elements are made of Incoloy 800 (Nickel alloy) tube

with a diameter of 3/8” (9.5mm) which contains a heating coil in magnesium oxide powder. Finned tubular elements have

aluminum fins installed on the tube to allow a higher heat dissipation capacity. | |

|

|

|

|

|

Forced/Forced Air Heaters

| NEP - Therm heaters are designed to complement heating systems

of homes and offices by preheating fresh air or returned air with any existing central forced-air heating system. | |

|

| This electric duct heater is equipped with a modulating controller

that allows operating in extremely low air flow with peak performance. | |

|

| Applications and features: |

|

| • Heat recovery ventilation system. |

| • Central forced-air heating system. |

| • Air make-up combined with a small fan. |

| • Zone heater…. and more. |

| • 6" or 8" collar; 1 kW to 5 kW at 120, 208 or 240 VAC. |

| • 5 different kits of thermostat configuration available.

|

|

|

|

|

|